CFRP-Metal-Hybrid Load-Introduction-Elements for Highly Stressed Fiber Composite Structures

The aim of this research project is to develop an intrinsic hybrid interface and its manufacturing process. The interface is characterized by a load-optimized pinned structure which allows a uniform transfer of loads at the transition metallic structure into highly stressed, complex fiber-plastic composite structures. For this purpose, an intrinsically produced multilayer insert (MLI) is developed. This insert forms a novel interface for this partial structure attachment. The CFRP considered here can be used, for example, in aircraft construction or automotive engineering in the future.

The aim of this research project is to develop an intrinsic hybrid interface and its manufacturing process. The interface is characterized by a load-optimized pinned structure which allows a uniform transfer of loads at the transition metallic structure into highly stressed, complex fiber-plastic composite structures. For this purpose, an intrinsically produced multilayer insert (MLI) is developed. This insert forms a novel interface for this partial structure attachment. The CFRP considered here can be used, for example, in aircraft construction or automotive engineering in the future.

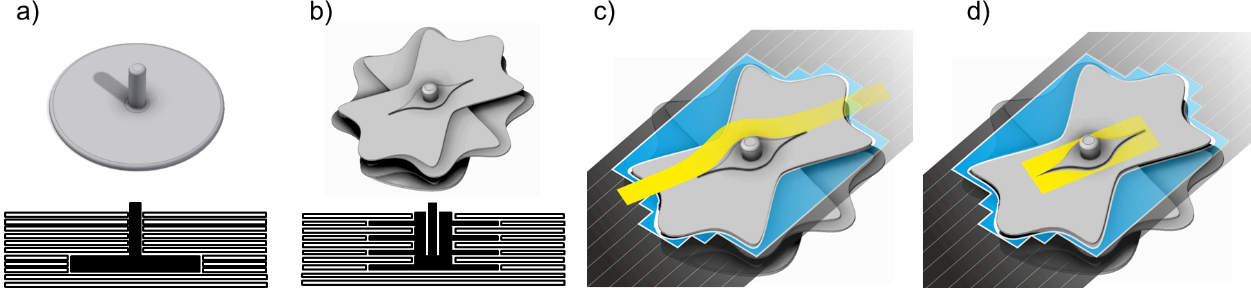

In the intrinsic hybridization process several metallic layers are successively built up as part of the automated tape-laying process to form an MLI inside the simultaneously generated composite layup. This is done in an Automated Fiber Placement Process (AFP). The orientation of the individual layers, their shape and their material properties are optimized according to the requirements of the interface. The way the MLI is integrated into the layup avoids an increase in the local laminate thickness. The illustrative example shows the idea of the new MLI (b) compared to a conventional insert (a). In the manufacturing process, the MLI is built up on a base plate on which it is centered by a stud bolt for example. With new composite layers, additional MLIs are added to the laminate and centered on the underlying layers. Their shape is based on the fiber orientation of the closest CFRP layer. In order to minimize the limitating influences of the MLI on the AFP process which are introduced for example by the centering bolt, material additives are placed in its vicinity to fill the area which cannot be reached by the laying head. They are designed in such a way that the tows can be laid-up around them (c) or attached to the stud (d) up to an additional prepreg patch.

In order to achieve the development goal, close co-operation between simulation and design, material science and production technology is carried out. The process of hybridization within the production of CFRP structures using AFP technologies is being developed. An additional development is a newly designed end effector for the process-integrated laying of metallic single layers of the MLI. In order to increase reliability during the production of complex structures, a simulation-based monitoring and control approach is developed and implemented in the system. Special materials for the individual layers of the MLI are researched and determined. They have to meet the special requirements caused by perpendicular to the laminate plane load introduction. The boundary layer behavior of the material combination in the CFRP is researched as well. For the design of the hybrid MLI component, models of material behavior are developed in the process and application. Based on those models, calculation models for the load-optimized design of individual MLI layers as well as the influence of the MLI on the bearing behavior of hybridized high-performance laminates are developed. Along with the validation of the methods and prototyping systems described here, a technology-potential-analysis for future new applications is carried out.

Funding: German Research Foundation (DFG)

Duration: 2014-2017, 2017 – 2020